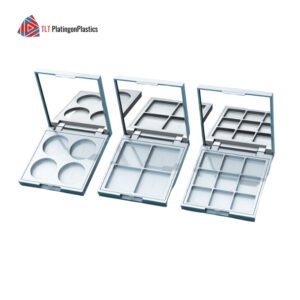

Plastic Vacuum Plating PVD Pure Color for Plastic Components for All Industries

| Process Used | PVD |

|---|---|

| Mimimum Order Quantity | 3000pcs for our style, 10000pcs for customized style. |

| Sample Leadtime | 3-45 Days |

| Production Leadtime | 10-20 Days |

| Material: | ABS, ABS+PC, NYLON, PC, PE |

The Certificates We have

Details About Plastic Vacuum Plating PVD Pure Color for Plastic Components for All Industries

There are two common electroplating processes for plastic products: water plating and vacuum ion plating.

Vacuum ion plating, also known as vacuum electroplating, is now a relatively popular method. The products produced have a strong metallic feel and high brightness. Compared with other coating methods, the cost is lower and the pollution to the environment is small. It is now widely used in various industries.

Vacuum electroplating has a wide range of applications, such as ABS materials, ABS+PC materials, and PC material products. At the same time, because of its complex process flow, and high environmental and equipment requirements, the unit price is more expensive than water electroplating. Here is a brief introduction to its process flow: Products Surface cleaning–>static removal–>spray primer–>baking primer–>vacuum coating–>spray topcoat–>baking topcoat–>packaging.

The general method of vacuum plating is to spray a layer of primer on the material before electroplating. Since the material is plastic, air bubbles, and organic gases will remain during injection molding and moisture in the air will be absorbed when placed. In addition, because the plastic surface is not flat enough, the surface of the directly plated workpiece is not smooth, has low gloss, poor metallic feel, and may cause bubbles, blisters, and other undesirable conditions. After spraying a layer of primer, a smooth and flat surface will be formed, and the generation of bubbles and blisters in the plastic itself will be eliminated, allowing the effect of electroplating to be displayed.

Vacuum electroplating can be divided into general vacuum electroplating, UV vacuum electroplating, and special vacuum electroplating. The processes include evaporation, sputtering, gun color, etc.

Bright Chrome is a Polished Chrome finish color. Chrome’s reputation for quality arises from the fashion for pure, contemporary lines. It gives the Coffee Machine Parts a sparkling which never dulls over time. Its versatility makes unlimited creativity possible when it comes to decorative touches.

Chrome Plating is created over a thick nickel underlay. It is a durable finish which is virtually impervious to wear or scratches. Its resistance to corrosion and common Coffee Machine products make it a benchmark in Home appliance decorations.

- Cleaning: Very easy

- Corrosion resistance:unexceptionable

- Scratch resistance: unexceptionable

- Resistance to cleaning products: unexceptionable

Share Plastic Vacuum Plating PVD Pure Color for Plastic Components for All Industries With Your Clients

Available Shipping Method

Ship By Air

Ship By Sea

Ship By Train

Ship By Express