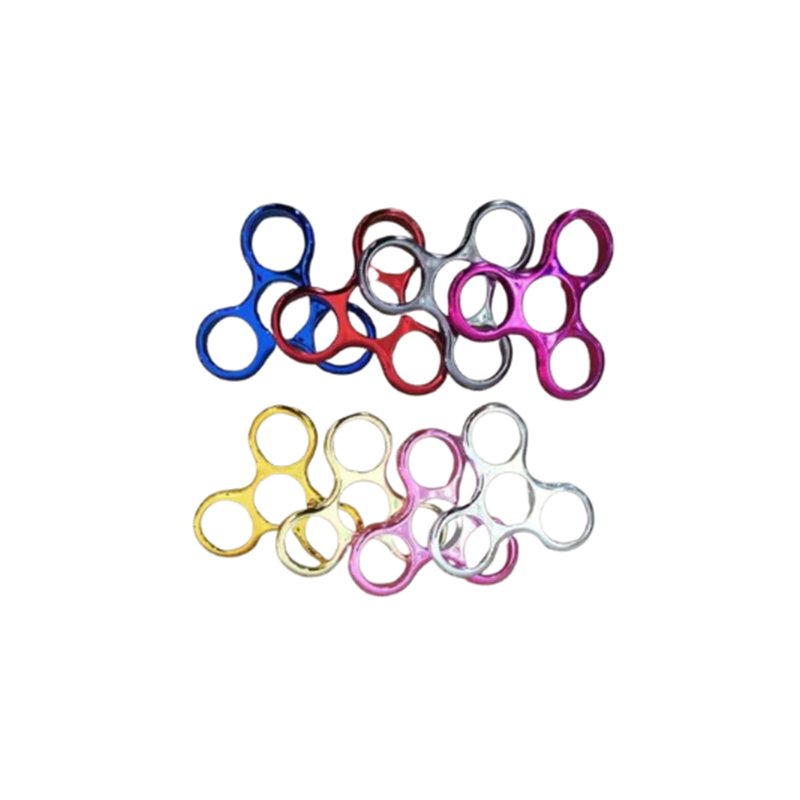

Plastic Vacuum Plating Multiple Color PVD

| Process Used | PVD |

|---|---|

| Mimimum Order Quantity | 3000pcs for our style, 10000pcs for customized style. |

| Sample Leadtime | 3-45 Days |

| Production Leadtime | 10-20 Days |

| Material: | ABS, ABS+PC, NYLON, PC, PE |

The Certificates We have

Details About Plastic Vacuum Plating Multiple Color PVD

Gradient color plastic bottle technology

Gradient color plastic bottle is a kind of bottle with a unique appearance. Its surface shows a smooth transition effect from one color to another. This process can give plastic bottles a more attractive appearance, increasing the product’s appeal and market competitiveness. The following will introduce the production process of gradient color plastic bottles

First of all, the production process of gradient-colored plastic bottles starts with the selection of raw materials. Generally, transparent or translucent plastic materials, such as PET (polyethylene terephthalate) or PP (polypropylene), are used as the raw materials for bottles. These plastic materials have good transparency and flexibility and can display gradient color effects well.

Next, the key to making gradient-colored plastic bottles lies in the color gradient process. A common method is to use a spray coating process. First, you need to prepare the desired gradient color. This can be achieved by mixing different colors of paint or dye. Then, use spray equipment to spray the paint evenly on the surface of the bottle.

During the spraying process, the spraying distance, spraying speed, and spraying angle need to be controlled to ensure a gradient effect of color. Generally, the closer the spraying distance, the smoother the color transition, the slower the spraying speed, the more delicate the color change, and the choice of spraying angle will also have an impact on the gradient effect.

In addition to the spraying process, other processes can also be used to achieve the gradient color effect. For example, special pigments or particles can be added to the raw material of the bottle to gradually change the color during the injection molding process. This method is generally suitable for small-scale production but may require more complex equipment and processes for large-scale production

Finally, the finished gradient plastic bottles need to be sprayed, cured, or baked to ensure the durability and stability of the color. At the same time, quality checks are also required to ensure that the bottles do not have any blemishes or defects

To sum up, the process of making gradient color plastic bottles includes raw material selection, color gradient process, and subsequent processing and inspection. This process can bring unique appearance effects to plastic bottles, improving product appeal and market competitiveness. Here are some key steps and techniques for making ombre plastic bottles:

Bright Chrome is a Polished Chrome finish color. Chrome’s reputation for quality arises from the fashion for pure, contemporary lines. It gives the Coffee Machine Parts a sparkling which never dulls over time. Its versatility makes unlimited creativity possible when it comes to decorative touches.

Chrome Plating is created over a thick nickel underlay. It is a durable finish which is virtually impervious to wear or scratches. Its resistance to corrosion and common Coffee Machine products make it a benchmark in Home appliance decorations.

- Cleaning: Very easy

- Corrosion resistance:unexceptionable

- Scratch resistance: unexceptionable

- Resistance to cleaning products: unexceptionable

Share Plastic Vacuum Plating Multiple Color PVD With Your Clients

Available Shipping Method

Ship By Air

Ship By Sea

Ship By Train

Ship By Express