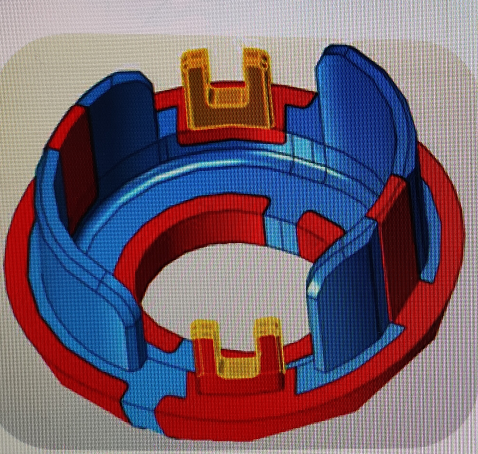

I. Appearance inspection and acceptance standards

A side usually refers to the most common side of the product, the surface must not have scratches, yellowing, leakage of plastic (bottom), water stains and other bad, pockmarks, convex/concave points, bubbles, pinholes, bright spots less than 0.15mm in diameter, point spacing of more than 30mm, normal visual inspection distance of 20cm visual not obvious, no hand feeling, brightness in line with the colour plate, no scratches (injury), no other electroplating defects.

B side usually refers to the side of the product, the surface can not have yellowed, leakage of plastic (bottom), water stains and other undesirable phenomena; surface pockmarks, convex/concave points, bubbles, pinholes, bright spots less than 0.2mm in diameter, point spacing in 20mm or more, normal visual distance of 20cm at the visual inspection is not obvious, no feel no scratch, colour to the colour plate.

Explicit plastic (bottom), special attention to the coating insulation oil bit may not be on the plating layer, the product must not be deformed.

C side

Usually refers to the product needing to be opened or dismantled to see the surface, and colour to the colour plate, the surface must not have a bright bubble, discolouration or other undesirable defects.

II. Safety performance test acceptance criteria

1、Ethanol test: Use a soft cloth with 95% concentration of medical alcohol and rub the surface of the product back and forth 50 times with a strength of 500g, the plating will not fall off, blistering, discolouration or other undesirable phenomena.

2、CASS salt spray test: put the product into the test chamber environment: 5% sodium chloride solution + copper chloride 0.26g/L, 45 degrees angle pulling 3 times, no obvious off plating (to achieve 4B effect). pH: 3.1-3. Temperature 50±2° C, relative humidity 85% or more, saturated barrel temperature 63±2° C, falling mist volume 1.0-2.0ml/80cm /h, compressed air pressure 1kgf/c. Compressed air pressure 1kgf/c m’ continuous test 24H product surface without stripping, blistering and other undesirable defects.

3、Adhesion test: use a lattice knife to cut a 1×1mm lattice on the surface of the product, use 3M600 adhesive tape to stick to the lattice, use a strength close to 60 degrees to tear off the tape smoothly, test result 0 level is excellent, 1 level is qualified.

4、Hot and cold shock test: put the product into the environment of -20℃ for 4H, and then put it into the environment of 70℃ for 4H in time for a cycle; do 5 cycles in total, no blistering, cracking, or discolouration and other bad phenomena in the plating.

5、Hardness test: Use China brand 2H pencil, apply 500g/45-degree oblique angle to scratch the 6.5mm length line, then use an eraser to erase pencil marks, no scratches or marks on the surface of the product.

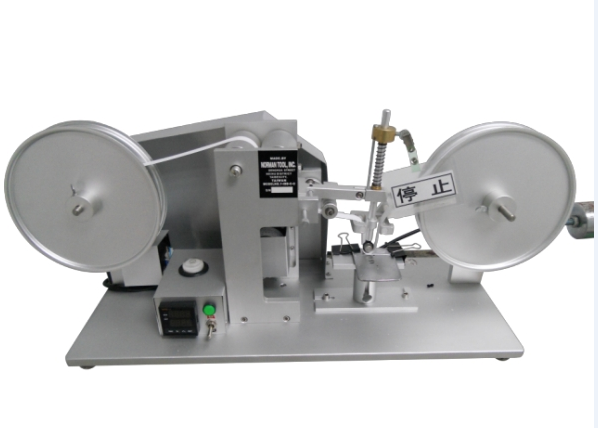

6、Abrasion test: fix the product on the abrasion test machine, and use the special abrasive paper to abrade the surface of the product 300 times with a force of 175g, the plating will not fall off, blister, discolouration or other undesirable defects.