Plastic surface decoration is an essential process in the production of various plastic products.

Plastic surface decoration is an essential process in the production of various plastic products. It enhances the aesthetic appeal of plastic products and also provides protection against environmental factors. There are several methods of plastic surface decoration, and one of the most common is plastic electroplating. In this article, we will focus on plastic electroplating, its color options, advantages, and more.

Plastic electroplating process

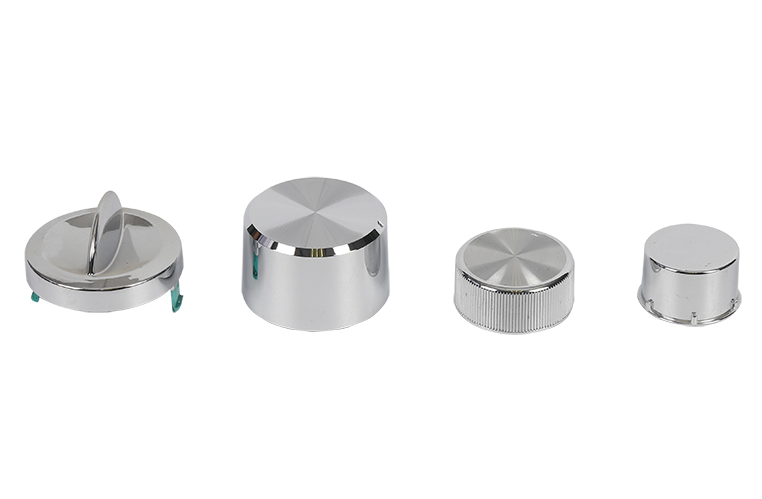

Plastic electroplating is a process that involves the deposition of a thin layer of metal on the plastic surface by applying an electric current. The process starts with cleaning the plastic surface to remove any dirt, oils, or other contaminants. Then, a conductive coating is applied to the surface, followed by electroplating the desired metal. The metal layer provides a protective coating that can also be colored to enhance the aesthetic appeal of the product.

The most commonly used metals for plastic electroplating are chrome, nickel, and gold. However, there are various other metals that can be used for this process, such as copper, silver, and zinc. The choice of metal depends on the desired color, finish, and durability.

When it comes to color options, plastic electroplating provides a wide range of choices. The most common colors include silver, gold, chrome, black, and various shades of copper. The color can be customized to meet the specific needs of the product, such as matching a brand color or creating a unique finish. The process can also be used to create a two-tone finish by combining different metals or colors.

In addition to providing a range of color options, plastic electroplating has several advantages. One of the most significant advantages is that it provides a durable and long-lasting finish. The metal layer protects the plastic surface from scratches, abrasions, and other environmental factors. This is especially important for products that are exposed to harsh conditions or frequent handling.

Another advantage of plastic electroplating is that it is a cost-effective process. Compared to other methods of plastic surface decoration, such as painting or vacuum metallization, electroplating provides a more cost-effective solution. The process is also relatively quick, allowing for high-volume production.

Plastic electroplating is also a versatile process that can be used for various types of plastic products. It can be applied to both rigid and flexible plastics, and it can be used for products of different sizes and shapes. This makes it an ideal solution for a wide range of industries, including automotive, electronics, and consumer goods.

However, there are some limitations to plastic electroplating. One of the main limitations is that it cannot be applied to all types of plastic. The plastic must be able to withstand the electroplating process without warping or melting. In addition, the process may not be suitable for products with intricate shapes or designs.

In conclusion, plastic electroplating is a popular and effective method of plastic surface decoration. It provides a range of color options, durability, and versatility, making it an ideal solution for various plastic products. However, it is essential to consider the limitations of the process before choosing it a specific product. With careful consideration, plastic electroplating can provide a high-quality and cost-effective finish for plastic products.